MG-Cars.com

Triumph TR6 Bronze Crank bearing BBS discussion at MG-Cars.net

MG-Cars.net

Welcome to our resource for MG Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - Bronze Crank bearing

| For those who MAY be following this long saga you'll know that I'm still working on my engine. Yesterday, quite by accident, I noted that the bronze bearing in the rear of the crank was turning with the clutch alignment tool, both in rotation and fore and aft. I THOUGHT that it was a tight fit when I pressed it into the crank, but now I'm wondering what gives and if I have to remove the clutch and flywheel again to figure this out. I don't think the bearing is supposed to move!@!!! Any comments?? db |

| Doug Baker |

| Doug I seem to remember this bearing is loose in the opening and free to move in any direction. I wouldn't worry about it. Mike |

| Michael Petryschuk |

| If your talking about the "pilot" bearing then I'm almost positive it should move freely. |

| JT White |

| Guys, I sure hope that you're right. Hate to tear that flywheel apart AGAIN!! Thanks. db |

| Doug Baker |

| If it is the bronze pilot bearing, It moves freely so that you can align it and the clutch plate with your alignment tool. Once you align it, then you tighten down your pressure plate to the flywheel to hold the pilot bearing and clutch plate in place. Once held in place, you can now slip the input shaft of the tranny into the rear of the engine. If the input shaft is not through the center of the clutch and pilot bearing, the clutch will get destroyed. |

| benji |

| If it is the bronze pilot bearing, It moves freely so that you can align it and the clutch plate with your alignment tool. Once you align it, then you tighten down your pressure plate to the flywheel to hold the pilot bearing and clutch plate in place. Once held in place, you can now slip the input shaft of the tranny into the rear of the engine. If the input shaft is not through the center of the clutch and pilot bearing, the clutch will not sit right which will create catastrophic results. |

| benji |

| Benji, I've tightened the flywheel and clutch down as far as they are going to go and the pilot bearing is loose, both in rotation and longitudinally. What do I do now? Remove the clutch and flywheel and replace the pilot bearing with a different size? I used an OEM bronze bearing with an alloy flywheel and a magic clutch kit from TRF. The alignment tool lines everything up, but the bearing spins and will move in and out probably 1/16" or so. Maybe I put the flywheel on backwards...ye think?? db |

| Doug Baker |

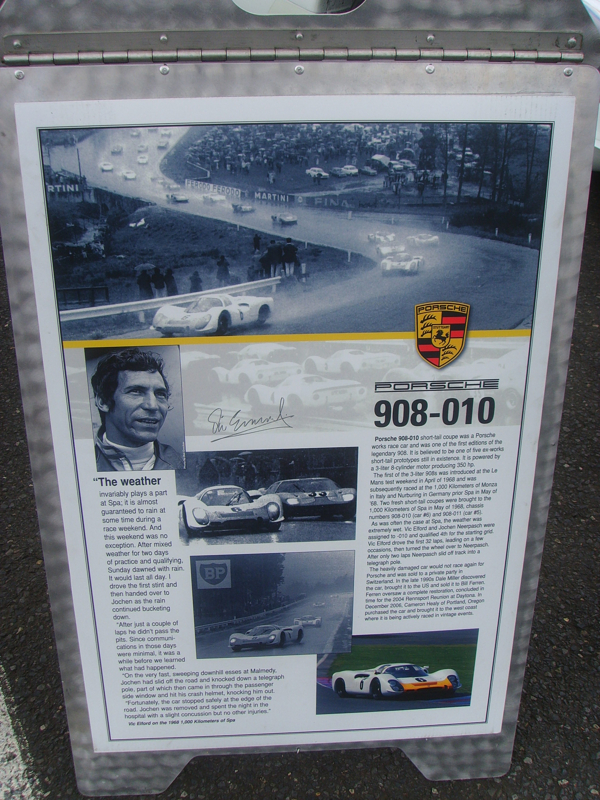

Please refer to the image. In my left hand is a pilot bushing that goes in the middle of the flywheel. So, first, are we talking about the same thing? Please respond back asap. I need to go to work pretty soon.

|

| benji |

| In the grand scheme of things, it doesn't make any difference if the clutch pilot bearing rotates in the crank recess or is a light press fit. The bearings only purpose is to support the pilot on the end of the imput shaft. A slight amount of end play shouldn't matter either. I would have probably staked the od of the bushing with a center punch to hold it in place and if it would eliminate a source of worry, you can remove the clutch and still do it. A dab of blue loctite could also be used. Berry |

| BTP Price |

| To further what you're saying Berry, the input shaft MUST go through the center of the bushing. I installed my tranny w/o sitting the input shaft correctly and destroyed my clutch. BTW, great idea about the loctite. I'm always learning new things from you guys! Thanks. Hope to see ya' Berry this weekend at the Portland Raceway!! |

| benji |

| Hi Benji-I just assumed (usually gets me in trouble) that the input shaft went into the bearing. I will be at the ABFM Sun. Hopefully, in a red 6 with AR wheels. Berry |

| BTP Price |

| Benji, yep, that's it, but mine did not have a cut down like yours shows and I put in the recess in the crank, not in the flywheel. db |

| Doug Baker |

| Berry, it the input shaft is properly in the pilot bearing BUT the bearing is sloppy in the crank, would it not wear prematurely? db |

| Doug Baker |

| Berry, no Sat? |

| DON KELLY |

| Doug-I am assuming that the od of the bearing is a close fit in the crank-no more than .001" or so clearance,just not close enough to be an interference fit. Don-I usually try to make the Sun. swap meet, but my attention span is too short to do all 3 days. I didn't even do the drive in BC because it conflicted with the birth of our first grandchild. Berry |

| BTP Price |

| You driving in to the swap meet or parking out side. I will actually have a little poster sign on my car this year. You won't be there to see it so maybe will run into you on Sun. |

| DON KELLY |

| Doug, Sorry for the confusion, but that was the only picture I had. I have a cut down on my bearing because Iím using a Toyota tranny which has a different snout on the input shaft. Anyways, it seems to me that 1/16th is too much play. Hopefully someone will jump in a comment on that. When youíre banginí through the gears, I donít know if that play will effect it much. Mine has play but doesnít have 1/16thĒ play. Iíd call the place where you purchased that alloy flywheel and ask what they recommend. Berry, a couple of years ago, I re-installed my tranny from the interior side. I angled it in and did not have the input shaft go through the middle of the pilot bearing. The clutch ripped up to pieces. Maybe someone will learn from my bonehead mistakes. Don, What sign are you putting on your car? Are you selling it? |

| benji |

| Dave, at TRF says no play in bushing. I assume it should be "fixed" in the crank and the input shaft rotate in the bearing. Looks like I have to remove the clutch and flywheel to mic the bushing, crank "hole" and transmission input shaft to establish what relationships I now have, although there's no guarantee that I'll be using the same input shaft when I get done with the transmission. Bummer. Thought I'd buttoned this thing up for good. Got locktite on all bolts in the clutch/flywheel/crank connections. Hope I don't strip another set of threads in the flywheel!!! Thanks for all comments. db |

| Doug Baker |

| Doug-At the risk of beating the topic to death, I looked in my old TR3 factory manual (basically the same trans). It gives a lot of specs that don't seem to appear in other manuals. Anyway,it lists the clearance between the input shaft pilot and the pilot bearing as .0058"-.0085", which is incredibly sloppy. The bushings are oilite, which are produced by forcing bronze powder into a cavity, leaving porosity that is filled with oil. The id can't be machined as that would "close the pores"and aren't as precise in size as a machined bushing would be. A long time ago, there was a similar discussion on the 6pack list about the bushing rotating in the crank or flywheel and it was kinda decided that it didn't make any difference as long as the bushing was a very close fit. Benji-Was your problem caused by the bushing sliding out of contact with the pilot? Don-I should be parking inside, unless the rules have changed. Berry |

| BTP Price |

| Berry, Thanks and I hope no one thinks I'm beating this, but I'm still a bit confused. The bearing is "loose" in the crank. I can turn it 360 with just my finger and it moves forward/aft about a 1/16". Dave at TRF says the forward aft movement is no problem, but the bushing/bearing should be firm in the crank. It's a new bushing!! I oiled it really good!! Would another new bushing be any more apt to have an interference fit than the one I've installed? How to I get the damn thing to fit tightly enough to not screw up the transmission or clutch when I button it all up. Need some help here guys. I really don't want to take that clutch and flywheel off again if it can be helped. All comments/thoughts welcomed. Thanks. db |

| Doug Baker |

| Doug when I switched over to the HVDA toy 5 speed kit, the bush supplied by Herman was just a slip in fit, not tight. Three years later and a lot of high revving at the slaloms, not problem so far. Rob |

| rw loftus |

| Doug, how could one get fwd/aft movement BUT not get circular motion...I think the gentlemen at TRF should re-think his statment a bit. If there is no holding provision for 360 motion in a key-way/groove & slot then it naturally would spin 360 if allowed fwd/aft travel. I hope you can see the logic in that. |

| JT White |

| OK, JT, your logic is sound. Now do I replace the damn thing or forget it??? db |

| Doug Baker |

Doug , bag that thing and buy one of these

|

| DON KELLY |

| Get a 74....I hear they are trouble free! |

| JT White |

| Pretty Funny |

| DON KELLY |

| Don, I don't even know what the hell that thing is, but I do like the new gullwing Mercedes, I think!! db |

| Doug Baker |

Here this might help

|

| DON KELLY |

| Ok, ok, it comes back to me now!! db |

| Doug Baker |

| Gentlemen...Bentley Manual, Operation 3.12.21.45..."Fit the Spigot bush into the back of the flywheel ensuring that it is a LOOSE fit." Now, I've read literally dozens of comments that argue for an interference fit. I'm still a bit confused since I put my bushing in the crank and not the flywheel, but it does say a loose fit and mine definitely is so...think I'll leave it where it is. db |

| Doug Baker |

| Doug, remember the sage words of your mother. If everybody jumped off the cliff ,would you follow? |

| DON KELLY |

| Don You know my Mother!!!?? db |

| Doug Baker |

| Universally |

| DON KELLY |

This thread was discussed between 30/08/2010 and 10/09/2010

Triumph TR6 index